Periodical inspections of radio communications networks, performed by our company, allow to identify all the elements that got damaged during their exploitation time. Such inspections allow to prevent building up the effects of various damages and minimize the danger of lack of communication found especially in a critical moment, i.e. when it is most desired.

Measurements of electrical parameters

Basically, the inspection focuses on measuring transmitting and receiving parameters: transmitted power, frequency, deviation, sensitivity, current draw. All deviations from certain standards allow to identify damages in a radiotelephone itself as well as in its power supply unit.

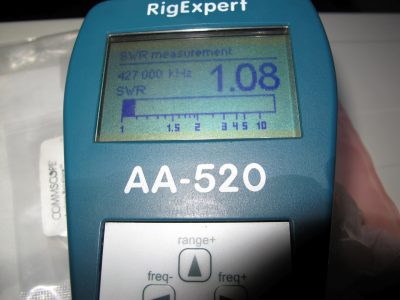

Checking (SWR/DTF) aerial parameters allows to locate the damage of an antenna system. Another significant point is also checking the condition of supply devices (power supplies, converters, power regulators) and the capacity of the batteries the devices are equipped with.

- Measuring antenna tower guy rope wire tension.

- Measuring of an EMF field needed for electromagnetic certificate.

- Flashing of a retransmitting station in a JTI plant.

- Measuring of an earth resistance (District Quarters of the State Fire Service Mława).

Inspection of devices physical condition

Generally, it is based on checking the physical condition of the network elements which are said to get damaged most frequently because of exploitation conditions. The state of particular elements is mostly affected by, e.g. the way they are used, weather conditions, vibrations or dustiness.

This stage allows to ‘fish out’ all the damages of mechanical nature, e.g. loosening of the radiotelephone, masts or aerials fitting elements, damages of push-buttons, sockets and plugs and physical damage of cords.

Procedure

Some of the repairs and adjusting are performed yet during inspection. The repairs requiring the use of more specialised tools and measuring devices are done in our radiocommunications service center. Inspections of radiotelephones are conducted by means of model radiotelephone testers made by Hewlett Packard and Aeroflex, whereas aerial installations by means of the testing devices Sitemaster provided by Anritsu.

Inspections of radiotelephones only (excluding antenna installations) can be executed directly in our service centre without the necessity of visiting a client (the devices to be checked are sent to us by courier mail). This solution is usually cheaper as there is no need to cover the costs of travelling to the place where the service is supposed to be done. In other cases, our services can be performed in any place in Poland where the equipment is used.

Our inspections are held either on the basis of a single order (summary proceedings) or on the basis of a permanent contract (periodic mode). In the second case, the agreement determines duration of inspections and their frequency (e.g. once a month).

Our service agreement can be extended to repairing broken pieces of equipment in our service centre, within the earlier agreed time, with the option of providing a client with replacement equipment for the whole time of the repair. This option seems to be particularly significant in case of RRL networks equipped with crucial infrastructure (i.e. operating centres, retransmitting stations, base stations TETRA) that is, „Mission Critical” segment.